Regenerative turbine pumps

Regenerative turbine pumps (also known as peripheral pumps or turbine pumps) are hydraulic continuous-flow machines and a sub-type of centrifugal pump. They are classed as hydrodynamic pumps.

Circutec is one of the most capable and innovative providers of regenerative turbine pumps in the world, and boasts decades of experience in developing and manufacturing these pumps.

Areas of application

- Particularly suitable for high pressures and/or delivery pressures at relatively low flow rates

- Suitable for clear or cloudy liquids with no abrasive contamination or solid content, and which have a kinetic viscosity of up to 100 mm²/s

Design

- Circutec can offer you a wide spectrum of regenerative turbine pump outputs with many different constructive designs and drive types.

- Compared to centrifugal pumps, they have considerably smaller dimensions and a simpler construction

- Suitable for the delivery of gas shares

- Delivering media pulsation-free

- Reversible, i.e. it is possible to change the delivery direction (upon request)

- Stable characteristic curves, even in varying operating states

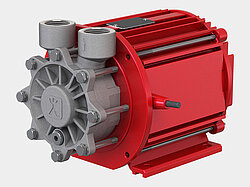

Close-coupled pumps with magnetic coupling

Advantages

- High-quality, robust and reliable pumps for continuous operation

- Leakage-free, low-maintenance and safe in operation

Description

- Pump shaft made from ceramic, sleeve bearings made from SiC

- Connection position top/top, threaded and SAE flanges

- Normal-priming

- High-quality magnetic couplings

- Designs in stainless steel, spheroidal graphite cast iron, copper alloy and high-quality plastic

- Tmax

Water up to 180 °C

Oil up to 200 °C

Further media upon request - ATEX II 2GD IIC cb TX (except for EY-MK)

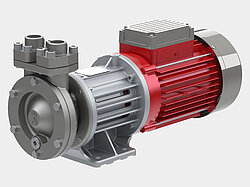

Heat transfer pumps with magnetic coupling

Advantages

- High-quality, robust and reliable pumps for continuous operation

- Leakage-free, low-maintenance and safe in operation

- Hot water version "HT" designed for high system pressures

- Thermal oil version "TOE" impervious to low-boilers in the delivery medium

Description

- Pump shaft made from ceramic, sleeve bearings made from SiC

- Connection position top/top, threaded and SAE flanges

- Normal-priming

- High-quality magnetic couplings

- Stainless steel and spheroidal graphite cast iron designs

- Tmax

Water up to 220 °C

Oil up to 400 °C

Further media upon request - ATEX II 2GD IIC cb TX

Close-coupled pumps with EC motor

Advantages

- High-quality and reliable pumps

- Extremely small dimensions

- SiC sleeve bearings

- Low-noise

- Drive without bearing

Description

- Pumps with magnetic coupling (…-MK), force transmission by outer magnet

- Pumps with canned motor (…-MM), force transmission by motor winding

- Drives with EC motors, 24 V (other voltages upon request)

- Designs in brass, stainless steel and high-quality plastic

- Connection positions top/top, threaded

- Tmax

Water up to 95 °C

Oil up to 90 °C

Further media upon request

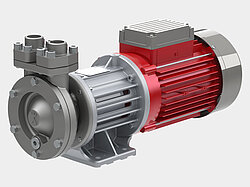

Close-coupled pumps with mechanical seal

Advantages

- Universally deployable pumps which are suitable for many industrial applications.

- Small dimensions

Description

- The motor shaft is the pump shaft

- Connection position top/top, ax/top upon request

- Threaded connections or SAE flanges

- Normal-priming, self-priming upon request

- Mechanical seal made from carbon, SiC or FKM. Other material designs are available upon request depending on the respective medium

- Designs in copper alloy, stainless steel and high-quality plastic

- Tmax

Water up to 140 °C

Oil up to 180 °C

Further media upon request - ATEX II 2GD IIC cb TX

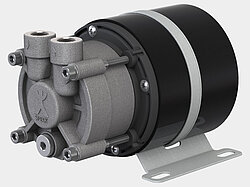

Sealless vertical pumps

Advantages

- Universally deployable pumps for open circuits

- Sealless and therefore maintenance-free

- Small dimensions

Description

- Vertical single-stage or multi-stage pumps

- Horizontal, threaded pressure connection

- Various submersion depths available

- Robust sleeve bearings

- Material designs:

T-401/601 in stainless steel

TM-201 – TM-701 in copper alloy

T-1001 – T-2001 in copper alloy

- Tmax

Water up to 90 °C

Oil up to 150 °C, up to 200 °C upon request

Further media upon request