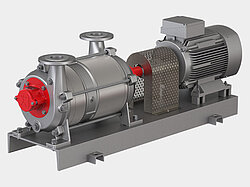

Liquid ring vacuum pumps

Liquid ring vacuum pumps are also known as water ring pumps, liquid ring pumps or liquid ring compressors.

For decades now, Circutec has been developing and manufacturing liquid ring vacuum pumps and has made a name for itself with its innovative, industry-specific advances in this field.

Areas of application

- They are used in many sectors in discontinuous and continuous operation in the three basic processes of extraction, leakage extraction and degasification, for example:

extracting dry gases, saturated gases and vapours

extracting contaminated gases

delivering liquid shares at a constant vacuum

delivering explosive gases, e.g. hydrogen - Oil-free compression, i.e. no oil in the medium nor in the exhaust air

- Minimum suction pressures possible up to 33 mbar abs., with gas ejectors (also known simply as "ejectors") even possible up to 5 mbar abs.

Design

- Wide spectrum of varied single- and two-stage, close-coupled and base plate pump construction designs

Liquid ring vacuum pumps

Advantages

- High-quality, reliable pumps which are suitable for many industrial applications.

- Great variety of graded pump sizes which span a large range of delivery volumes

- Broad portfolio of different designs: Robust standard designs, pumps that are free of dead space, pumps suitable for delivery of water shares, operating water-saving pumps and low-noise, two-stage pumps

Description

- Single-stage and two-stage pumps, with and without flap valves

- Close-coupled pumps and base plate pumps

- Mechanical seals, depending on the medium

- Usually with a single mechanical seal, but also available with a double-acting mechanical seal

- VZ model series also with a magnetic coupling

- Various material designs: Copper alloy, grey cast iron and stainless steel

- Base plate pumps with type examination certificate and ATEX (II 1G IIB+H2 cbk TX)

- Close-coupled pumps with ATEX II 2G cb TX

UniVac

Advantages

- Plug-and-play vacuum units which are mechanically ready to connect – developed for sterilisers

- Also for other applications such as degasification, drying and distilling

- Extremely compact, completely pre-assembled and easy to maintain

- Highly effective two-stage separator tank

Description

- Vacuum units comprising liquid ring vacuum pumps, separator tank, condenser and optional heat exchanger

- Integration of additional components such as gas ejectors, valve technology or exhaust gas condenser upon request

- UniVac-…-1 with robust, single-stage vacuum pumps from model series V

- UniVac-…-2 with quiet, two-stage vacuum pumps from model series VZ

- Material design in grey cast iron (UniVac-10-1 in copper alloy)