Centrifugal pumps

Centrifugal pumps (also known as rotary pumps, radial pumps or radial wheel pumps) are hydraulic continuous-flow machines.

For decades now, Circutec has been developing and manufacturing application-specific centrifugal pumps and setting new standards, especially with its innovative modular heat transfer pump system.

With a cutting-edge testing area for tests up to 750 m³/h and 400 m, Circutec boasts an outstanding framework for research, development and series testing.

Areas of application

- Particularly well suited for high flow rates at relatively low pressures or delivery pressures

- Suitable for clear liquids with no abrasive contamination or solid content

- The adjustment to the operating point takes place by changing the impeller diameter; higher delivery pressures or higher pressures are achieved with multi-stage designs.

- Normal-priming, not suitable for the delivery of gas shares

Design

- Centrifugal pumps have enclosed impellers with a cover plate, and both open impellers and back vanes for small pumps with an EC motor

- Alongside single-stage pumps with a volute casing or inline casing, Circutec also offers horizontal, multi-stage pumps with modular design.

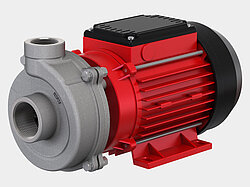

Close-coupled pumps with mechanical seal

Advantages

- Universally deployable pumps which are suitable for many applications

- Small dimensions

Description

- The motor shaft is the pump shaft

- Threaded connections

- Mechanical seal made from carbon, SiC and FKM. Other material designs are available upon request depending on the respective medium

- Grey cast iron, spheroidal graphite cast iron or stainless steel designs

- Tmax

Water up to 140 °C

Oil up to 160 °C

Further media upon request

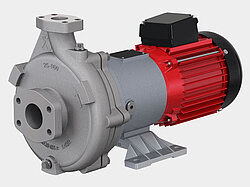

Close-coupled pumps with magnetic coupling

Advantages

- Universally deployable pumps which are suitable for many applications

- High-quality, robust and reliable pumps for continuous operation

- Low-maintenance and safe in operation

- Small dimensions

- High motor efficiency

Description

- High-quality magnetic couplings

- Threaded and SAE flanges

- Spheroidal graphite cast iron or stainless steel designs

- PM synchronous motor (VSD)

- Operation with frequency converter only

- Tmax

Water up to 160 °C

Oil -100 °C up to +300 °C, higher temperatures on request

Close-coupled pumps with EC motors

Advantages

- High-quality and reliable pumps

- Extremely small dimensions

- SiC sleeve bearings

- Low-noise

- Drive without bearing

Description

- Pumps with magnetic coupling (…-MK), force transmission by outer magnet

- Pumps with canned motor (…-MM), force transmission by motor winding

- Drives with EC motor, 24 V, 12 V upon request

- Designs made from high-quality plastic and stainless steel

- Tmax

Water up to 80 °C

Oil up to 80 °C

Further media upon request

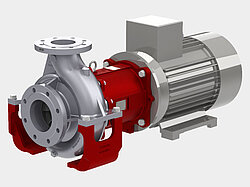

Heat transfer pumps

Advantages

- High-quality, reliable pumps for low- and high-temperature applications

- Safe in operation, easy to service and robust

Description

- Modular system with 6 model series

- Pumps with mechanical seal or magnetic coupling, with a volute casing or inline casing, with a base plate or bracket

- PN 16, bearing brackets 360 and 470

- Pumps with centreline mounting and/or double volutes

- Spheroidal graphite cast iron and stainless steel designs

- Tmax

Hot water up to 160 °C, up to 180 °C upon request

Heat transfer oils from -100 °C to 350 °C, up to 400 °C upon request - ATEX II 2GD IIC cb TX

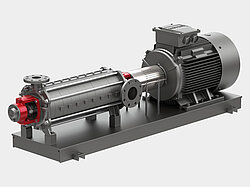

Boiler feed pumps

Advantages

- Reliable and universally deployable boiler feed pumps

- Modular system with 4 sizes

Description

- Horizontal pumps with modular design, with mechanical seal or stuffing box packing

- Robust external shaft bearings

- Hydraulically balanced impellers

- Grey cast iron or spheroidal graphite cast iron designs

- PN 40 and PN 63

- Tmax

Water up to 120 °C

Oil up to 120 °C

Further media upon request